We were asked to make 2 lamp shades one for each side of Vicki’s fireplace in Medicine Hat.

The next picture shows the lamps in our home prior to delivery to Vicki. The glass that she wanted gives off a very warm soft light. We used Spectrum glass SP 201.61S Ivory Opalescent, 1 inch sq bevels and the bottom glass is Uroboros art glass U-00-621 & U-65-540.

Close up of one of the shades by the fireplace.

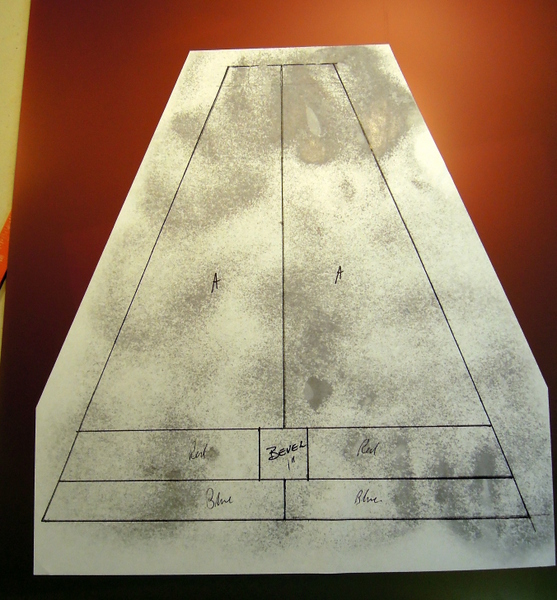

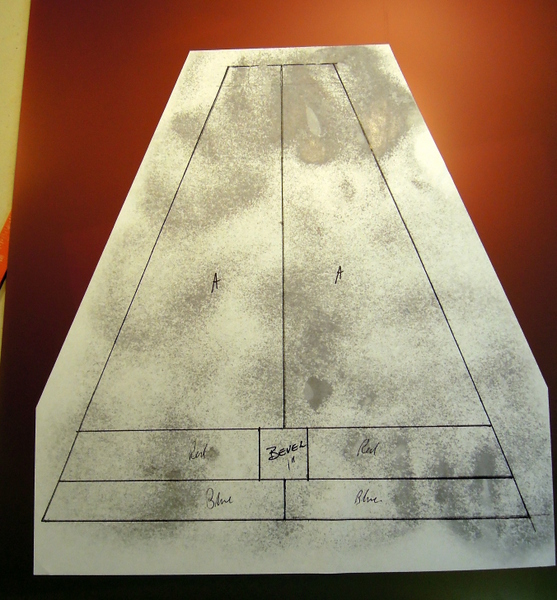

We took Vicki’s pattern design and transferred it onto X-Ray film. We then cut out each pattern piece and traced onto the respective glass to be used.

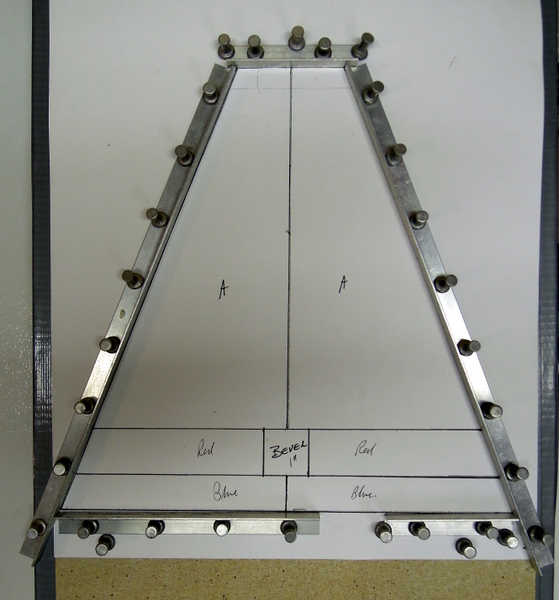

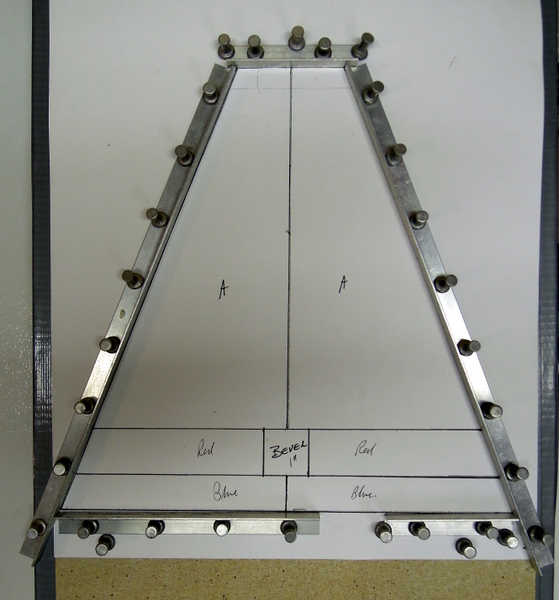

Using Morton layout blocks we set up this jig to allow us to make the 8 panels required for the 2 lamp shades.

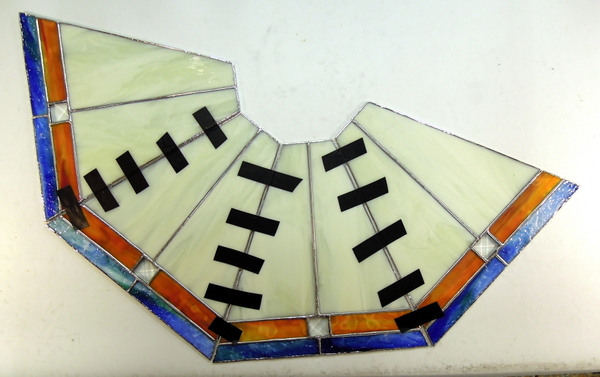

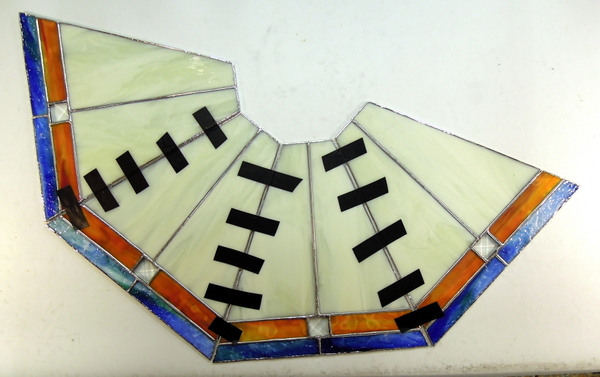

When tracing onto glass we made sure that the glass matched for the 2 top large panels. Then each piece was fitted, foiled and then soldered for each panel. We also ensured that the bottom pieces of Uroboros art glass matched as well.

Here is a photo of 1 of the panels after being soldered.

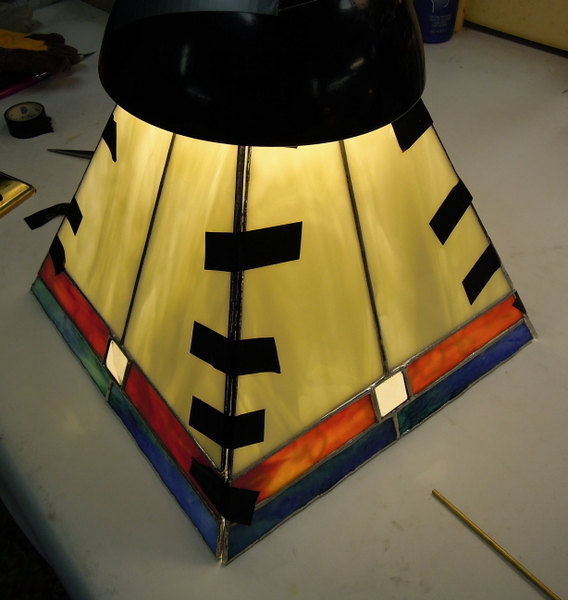

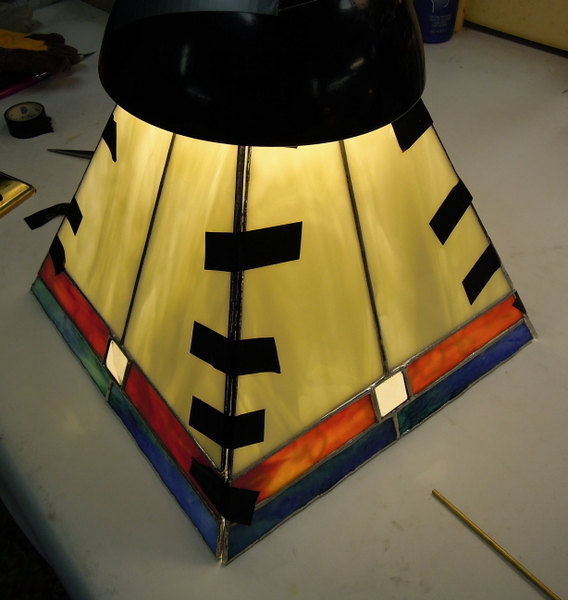

Once 4 panels were completed we laid them out, then joined them together with electrical tape.

After raising the 4 panels held together with electrical tape we put a light over the top to get and idea as to how the lamp shade would look when completed.

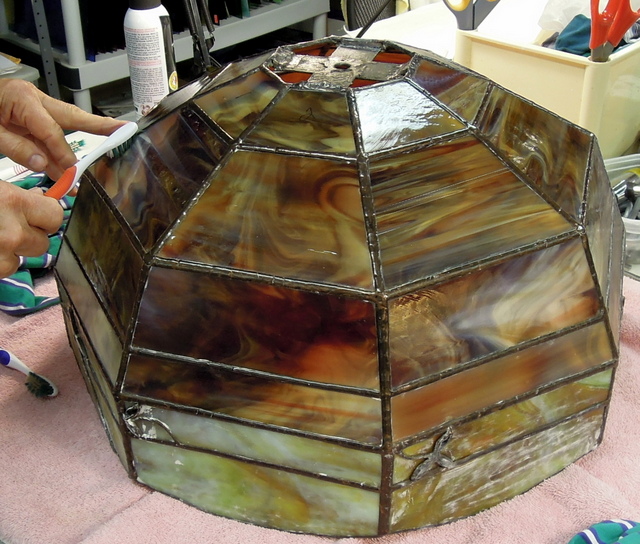

We then made sure that the lamps are level and square, touch solder the joints, and when sufficiently strong place the shade in a large box filled with newspaper. Using a small level we then fully bead each seam inside and out. We also used a 4 way spider for additional strength before soldering on the vented vase cap. Once completed each lamp shade is then cleaned with Kwik Clean, and this time we applied JAX pewter antique black patina, after which the shade must again be cleaned with Kwik Clean. Then Clarity stained glass polish is applied and the lamp shade is then polished using a soft cloth and toothbrushes on each seam.