The Sunnybrook Farm Museum is located north of the Bower Mall in Red Deer Alberta.

Here is the link to the Sunnybrook Farm Museum.

http://www.sunnybrookfarmmuseum.ca/

The picture below is of the Willowdale Zion Presbyterian Church at its new home on the museum grounds.

The photo below is of the church SE of Red Deer prior to it being moved in November of 2021 to the museum site.

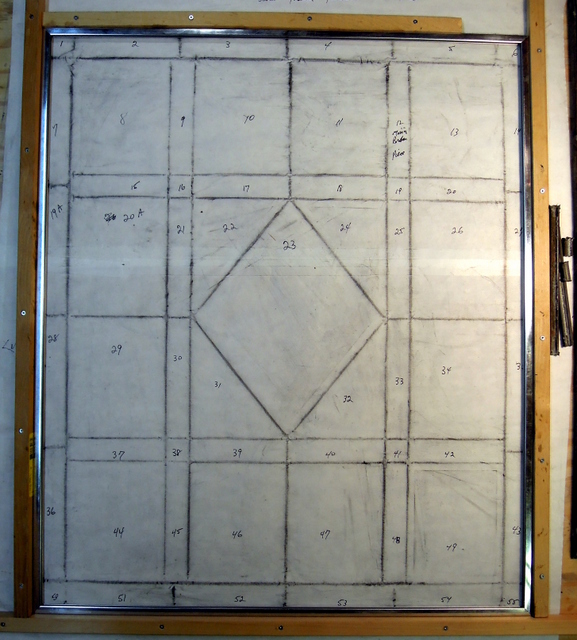

In the fall of 2021 Shunda Consulting & Construction Management Ltd contacted us regarding the moving of the Willowdale Zion Presbyterian Church from it’s rural location SE of Red Deer Alberta to the museum site. The church had 6 cathedral shaped stained glass windows measuring some 26 inches wide by 57 inches high and they wanted our input regarding how these windows could be preserved while they moved the church some 50 + kilometers. The church was moved in November 2021 and we were commissioned to do the work on the windows.

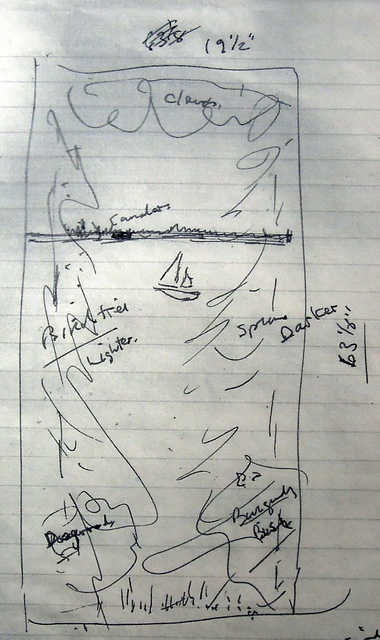

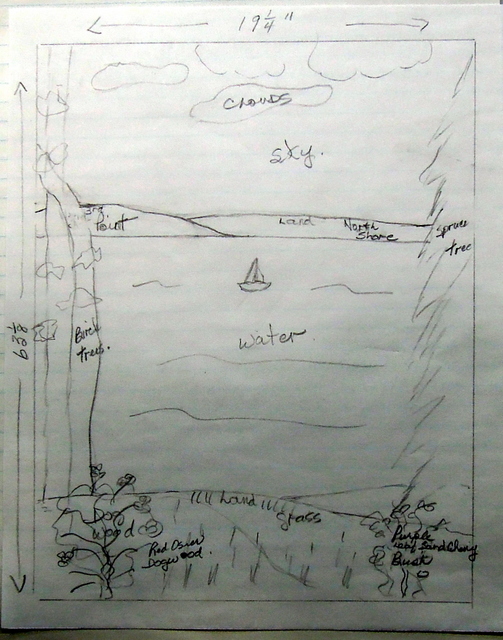

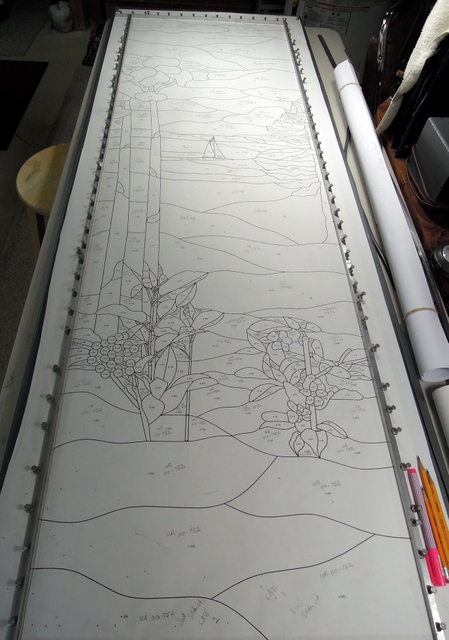

Subsequent to this the museum had donors that were very interested in putting 4 more new stained glass windows in the church once it was restored at the museum site. The donors gave us their ideas and we proceeded from there.

After the church was safely moved onto a new basement, lots of interior and exterior work was required, including all new windows.

It took many months and many trips from our studio here in Innisfail to Red Deer, to do all of this with the last new window just completed and installed in October 2023.

Stay tuned for the existing window restorations and the designs and construction of the 4 new windows.