For many years this very old came window rested secured under a bed. It measured 16 inches high by 40 inches wide. Was in poor structural condition as well had numerous lightly colored broken border pieces.

Our clients had just built a new home in a smaller Central Alberta community and wanted to have it restored to go into their new transom window above their front door entrance. But the new transom window measured 12 inches high by 49 inches wide, so we had to redesign the window to those measurements, as well as come up with a design that would use the existing glass.

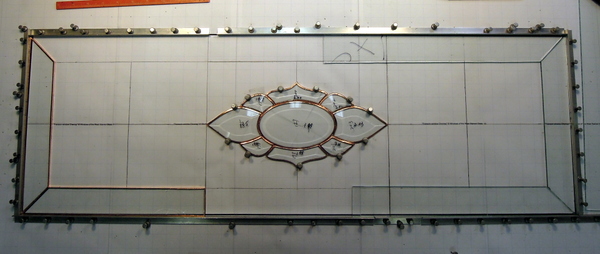

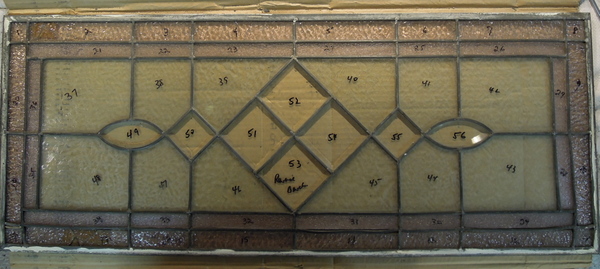

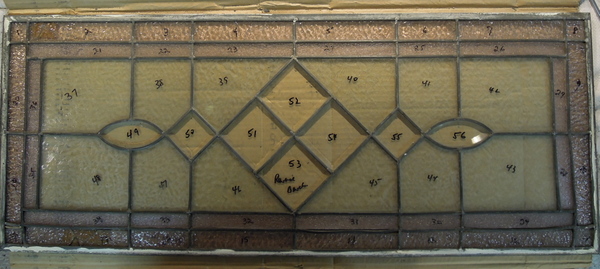

The following picture shows the window in it’s original condition.

Before we start a came restoration and after taking the initial photo we then number each piece and photograph the window again.

Then we proceed to carefully cut away the rotten came and sort each piece by color etc and place them in separate boxes – beer flats and smaller soup can cardboard flats work well as it provides lots of room to spread out the various varieties of glass.

We used to clean each piece and renumber but found that was more time consuming than just cleaning each piece when we are ready to use it in the reconstruction process.

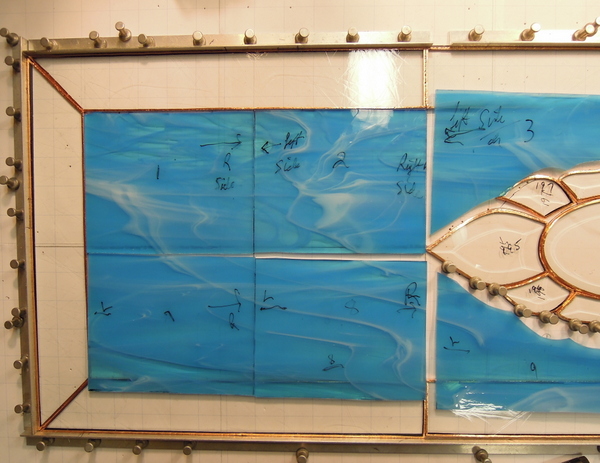

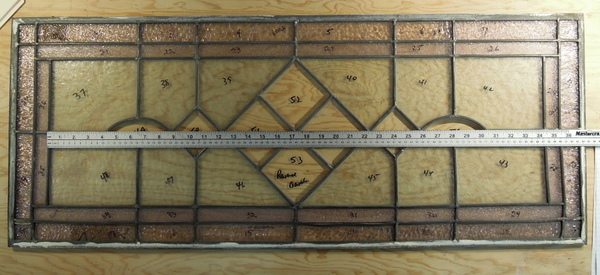

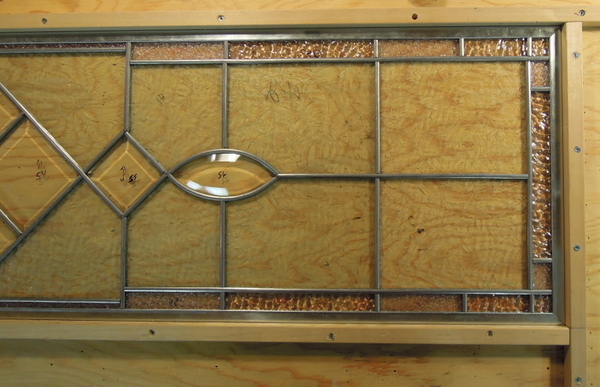

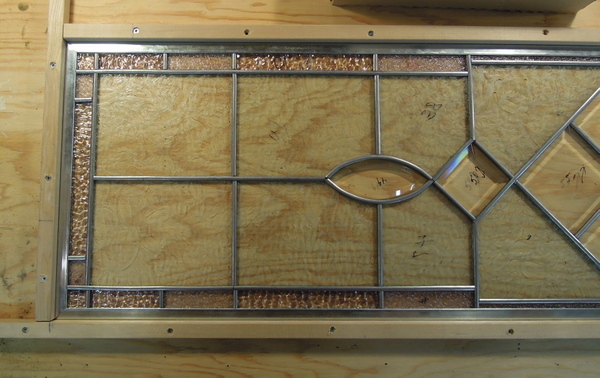

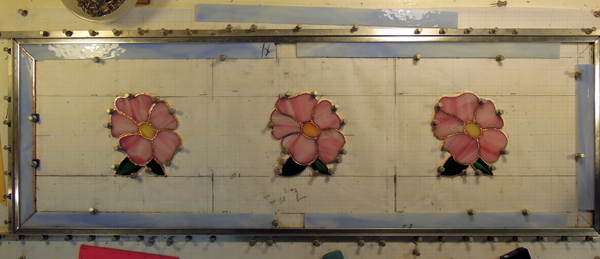

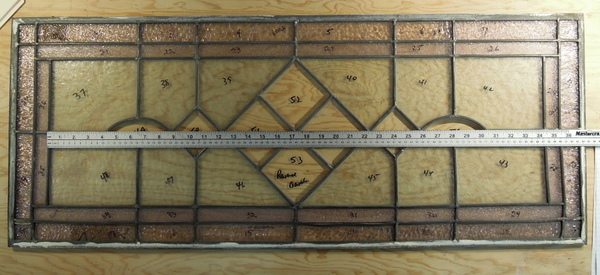

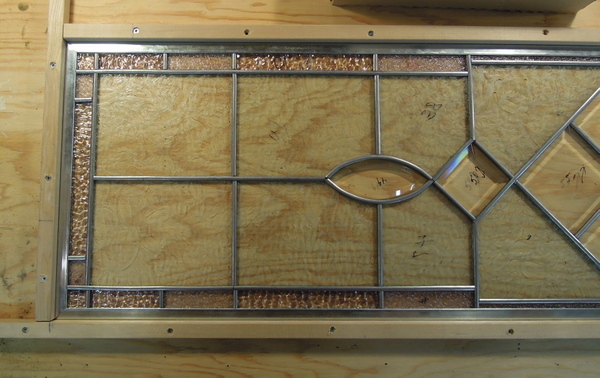

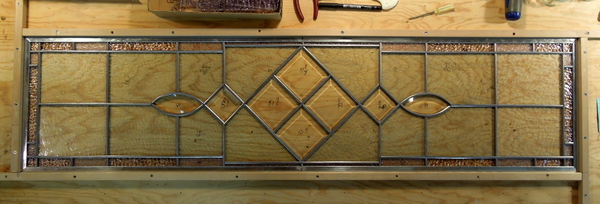

The next 2 pictures can give you an idea as to how much we had to stretch the length from 40 inches to 49 inches as well as shrink the height from 16 inches to 12 inches.

These measurements also included the new 1/2 inch came frame. We use a piece of 3/4 inch plywood for the base and make the frame from hickory hardwood with intermittently placed drill holes, then using fine wood screws we attached these frames to the plywood base.

You can see that we had to be creative to figure out how we would have enough of the colored border glass to go around.

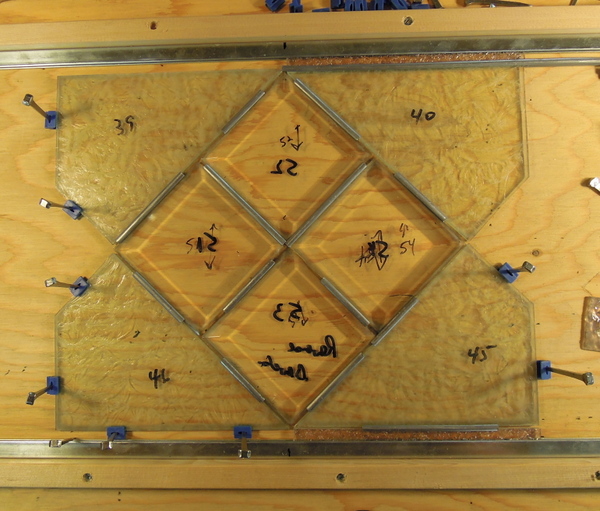

After numerous measurements to ensure final fitting accuracy, we built the wooden frame, miter cut the 1/2 zinc came frame and started the rebuilding process.

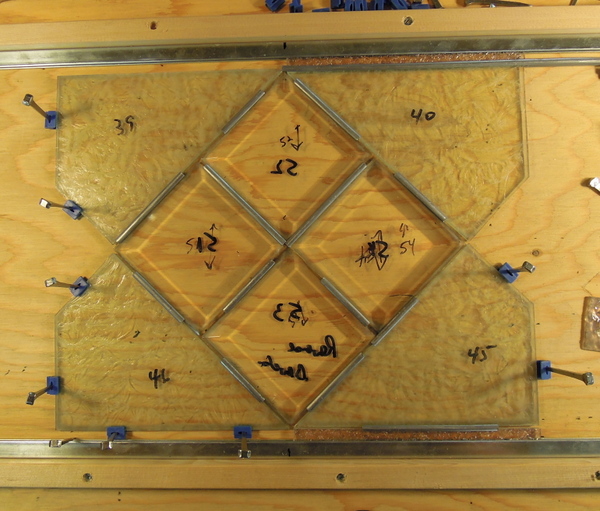

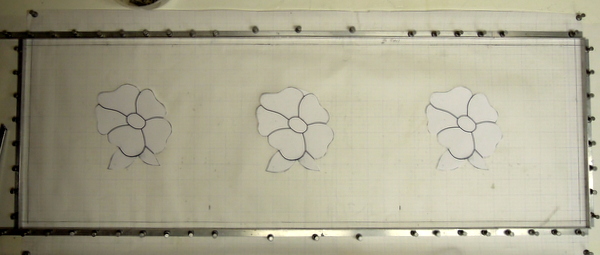

The following picture shows the start of the redesign process.

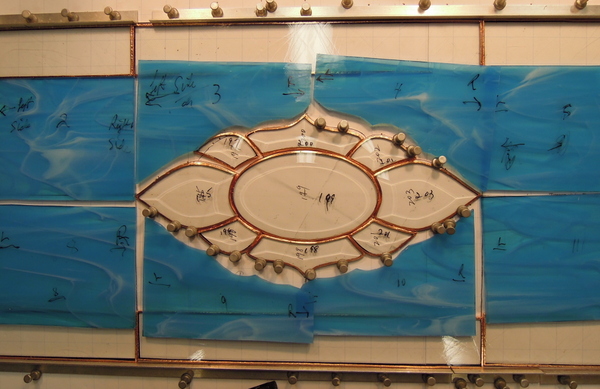

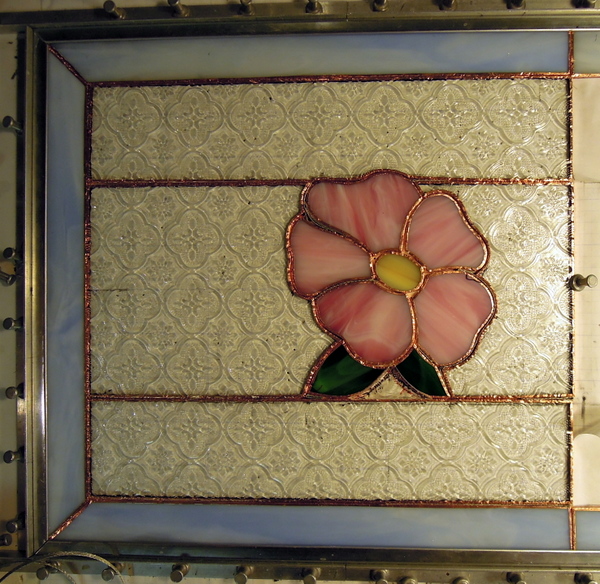

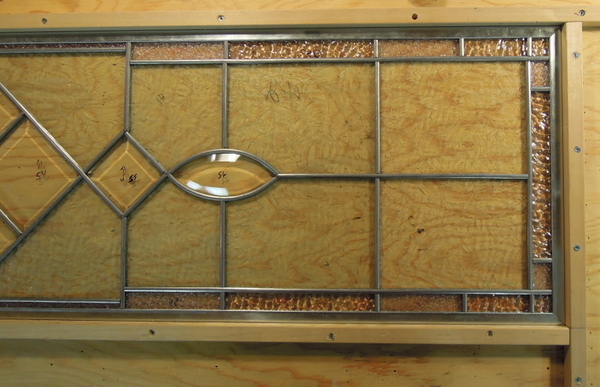

In the next photo we have expanded the left and right sides of the center bevel cluster, along with enlarging the colored border.

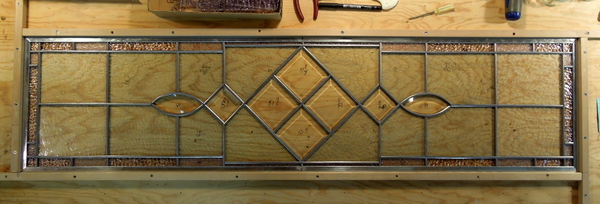

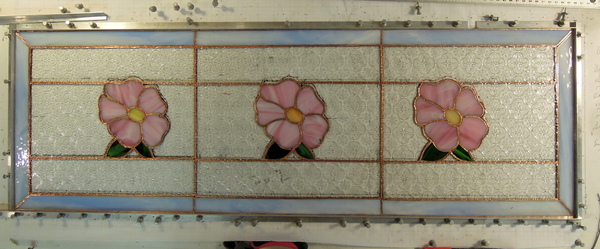

The following 2 photos show the completed redesign first the right side and then the left side.

In the next photo the redesigned window is ready for joint soldering, cementing, whiting, then patina and polish.

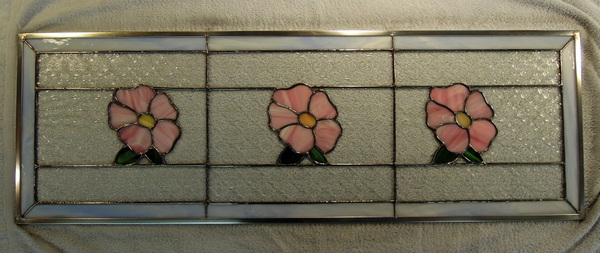

In the next picture the window is finished and ready to be taken to our clients. After soldering the came joints (cleaning the flux with Kwik Clean), cementing, cleaning with whiting, applying black patina to the came, cleaning again with Kwik Clean and applying polish, followed by lots of further cleaning, polishing with soft rags, along with using tooth brushes and X-acto knives to pick away any missed cement etc. we then have a beautiful window ready for our clients.

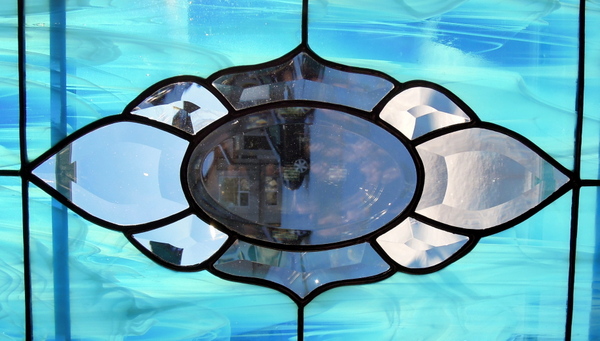

Here is the window installed in it’s new home location. Our clients were more than pleased with the results and how it fitted into the new transom window opening along with how it complimented the new door and sidelight beveled panels.

Redesign/Reconstruction by Bob & Flory Wilkins