Back in 2017 we were asked if we could restore this very old family crest – refer “110+ Year Old Family Crest Restoration” published on our Windows of the West Stained Glass website last October 23, 2018.

The following picture is of the completed Crest. There were 2 panels – the bottom one measured 23 1/2 inches wide by 30 inches high and top panel was 21 1/2 inches high. Combined the 2 panels were over 50 inches in height not counting the custom made laminated maple wooden frame.

Please note the Latin wording on the crest “Sua Cuique Voluptas” which has the meaning of “Everyone has his own pleasures” or “to teach his own pleasure”

The History of Henry John Frank Burroughes as provided by the Burroughes family members.

Henry John Frank Burroughes was born in 1864 in the Parish of Kentish Town, (now part of London England) in the County of Middlesex, England.

He was the eldest child of John & Jane Burroughes. At the age of 13 he was apprenticed to a firm of Stained-Glass Window makers, where he received the sum of 2/6 (shillings/pence) per week, rising to the sum of 15/- at 19. I believe that at the age of 21 he then earned 2 English Pounds (quid as it was commonly called) per week and his salary remained at that figure until 1914. The outbreak of the Great War caused the firm to close, as there was a declining popularity for stained-glass, and by then it was considered a luxury trade.

Times were very hard in those days, and if the firm had no orders in hand the men were just laid off with no pay. This was a great injustice as he was a skilled craftsman. Henry’s father was killed by a runaway horse, so being the eldest son he had to contribute money to his mother, until she died at 88.

The stained glass family crest was made by Henry John Frank Burroughes in England in 1906. It was in the Burroughes family England home for many years, until it came to Canada in the 1940’s. Then approximately around 1948 it was gifted to Lakefield Boys school – details are sketchy but outlined in the next paragraph is information that was provided by a volunteer who worked in the archives of the Lakefield College School, Lakefield Ontario.

“There is a new window in the east wall of the link between the dining-room and New Wing. It is a stained glass window and was donated by Mr. F.E. Burroughes the father of Grant. It is the work of Grant’s grandfather (Henry John Frank Burroughes) who enjoyed a reputation in England and Europe for his skill as a stained glass artist.”

Current History

We understand from our clients that eventually that wing of the Lakefield College School was going to be torn down and the family was asked if they would come and retrieve the stained glass family crest if they wanted it and that is what they did.

Our clients brought the stained glass window out west to Vancouver in 1993. They had a stained glass artist friend who thought they could restore it in the 90’s. That never happened. Eventually the stained glass window was picked up in 2004 and remained in Sylvan Lake until 2017.

In 2017, our clients brought it to our studio and we said we were quite willing to tackle the restoration of this historic piece of family stained glass.

Henry John Frank Burroughes was our clients great grandfather.

We and our clients mused that this was an opportunity to restore the family crest. “De.ja vu” is that Bob Wilkins was born in London, Ontario in the County of Middlesex.

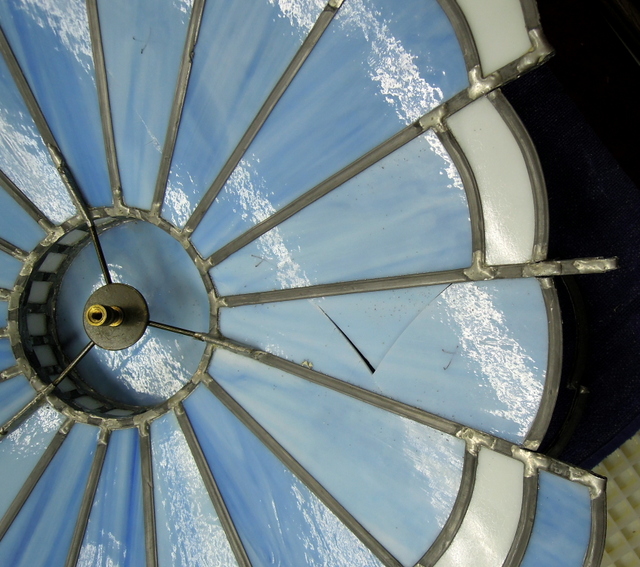

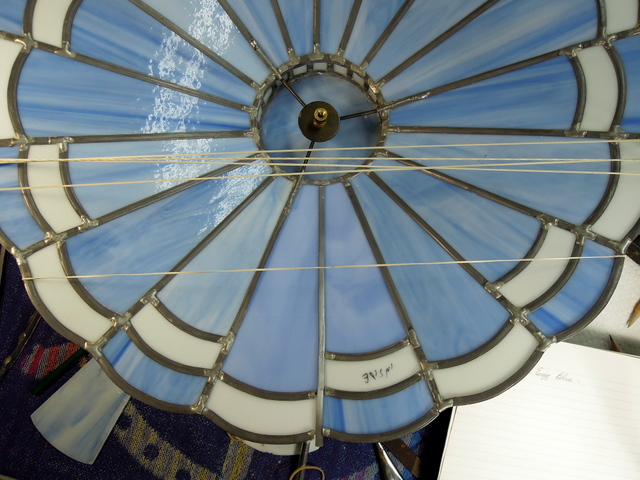

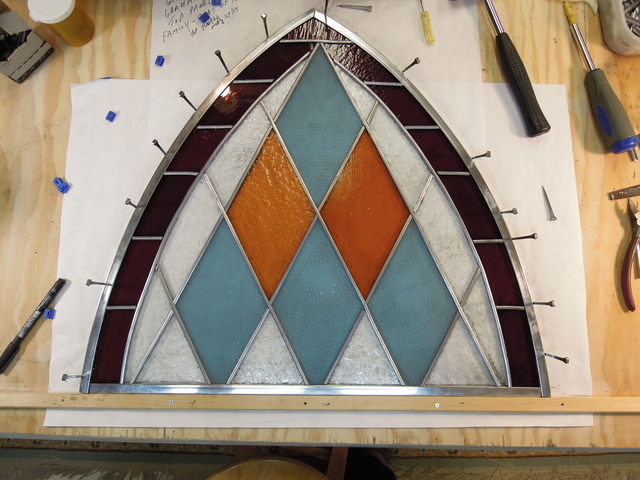

The following photos of the crest show it’s condition when we received it and we started with restoring the top portion first.

We number each piece and photographed the panel. Panel #’s 5,6,11,13 were all broken and at some point in time # 3 was replaced with that color hue piece. We were lucky to find a piece of Light Rose Brown glass manufactured in Poland many years ago. It have very similar color and hue but not quite the same texture but was as close to the original as we could find.

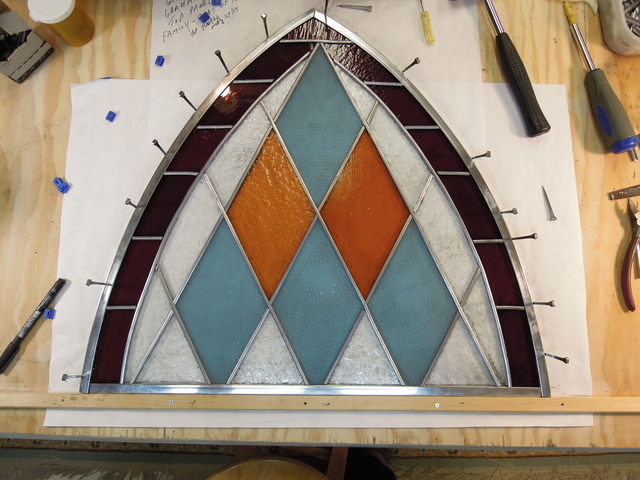

The panel was then completely taken apart and rebuilt from the bottom up, using the broken pieces etc as patterns for the new glass where necessary.

Each piece of glass was scrubbed clean using warm soapy water. #0000 steel wool where necessary, along with Mother’s Choice Natural Hard Surface Cleaner which is made from fine pumice and does an exceptional job in cleaning stained glass that has been exposed to the elements for decades.

The next photo shows the panel ready for soldering of the joints and the new 1/2 inch zinc came frame

After soldering of the joints, cementing the lead came, cleaning with whiting, allowing time for the cement to cure and harden, we then cleaned the came with #0000 steel wool (Any higher rated steel wool will scratch the glass) applied black patina. The panel was then cleaned with Kwik Clean and once dry we applied Clarity (Kemo-Pro) stained glass polish, buffing with soft cloths, along with using toothbrushes to get at all the polish residue especially around joints and very necessary when polishing glue chip and rougher glass surfaces.

The bottom portion being the Burroughes Family Crest was in very poor condition, with many broken pieces along with some of the fired crest pieces being cracked. Besides replacing the broken border pieces we redesigned the four corner pieces of the crest where all of the glue chip was broken, so as to prevent that occurring again in the future. Between the reddish interior border and the larger lead came frame, the majority of the clear glass was broken and we decided to replace all with an old Kokomo #33 GCP made in 1991.

We also had to match similar reddish border glass surrounding the outside of the crest.

Due to the age and the unknowns that we might encounter with this restoration we soaked the crest in a kids wading pool for quite some time to soften the old came and cement making it much easier to take apart. We were very glad we did as there were some cracked pieces. Also there were numerous thickness of the glass used especially the fired top left red piece as it was only 1 mil in thickness, while others were 3 mil and 5 mil.

The last picture shows the restored crest before cleaning and polishing. We were most fortunate to be able to call upon the decades of experience in the stained glass business of David & Crosby Haight of Rubaiyat Stained Glass Studio in Calgary, for helping us find old glass replacements. Several of the fired pieces were cracked and they helped us in using a special ultraviolet glue to glue the cracked fired pieces back together. This special glue dries clear and is very strong. The fired pieces of glass in the family crest were irreplaceable and great care was taken to ensure none were lost in the restoration process.

Original by Henry John Frank Burroughes circa 1895-1906

Restoration by Bob & Flory Wilkins 2017-2018