This old came stained glass door panel had reached the point where if it was not removed from the door it was in great jeopardy of collapsing and being ruined forever. As you can see in the picture below, the frame was coming apart. While not visible when you pushed slightly on the center, the whole panel moved in and out a lot and would completely fall apart if the door was slammed or someone pushed on the panel to open the door. Only 1 piece of glass was missing (the amber piece on the top right) while the rest was all in its original state. When restoring these old came panels we securely fasten a sheet of white freezer paper over the whole panel, then using carbon paper we do a rub to have a pattern for restoration.

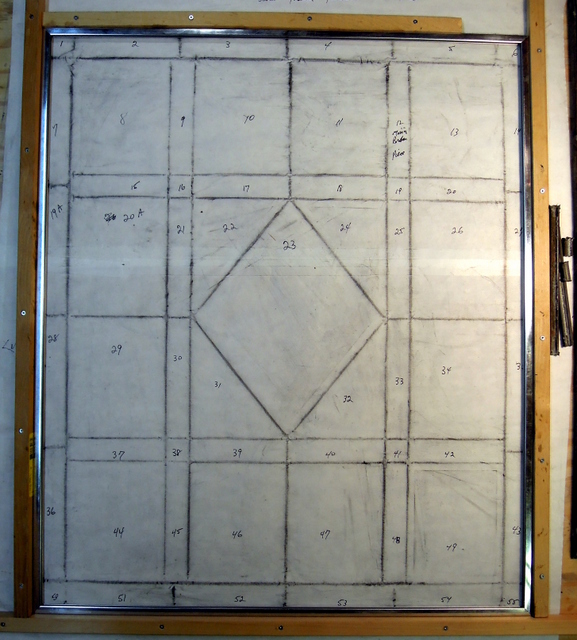

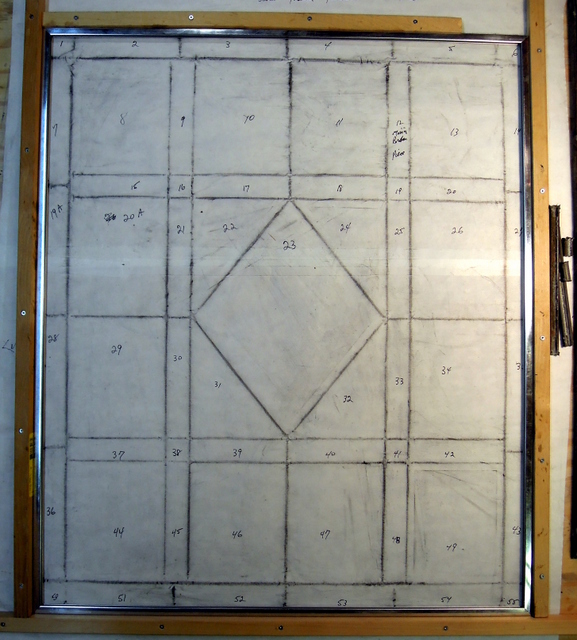

The panel measured 22 inches wide by 26 1/16 inches high including it’s 3/8 inch zinc frame. The process involves carefully removing the panel and transporting it to our studio. In the restoration process we take multiple photographs and number each glass piece. The challenge in this restoration was the very wide came originally used and not replaceable. The reason for the wide came was for the bevels which were made from very thick glass.

This presented a problem for restoration as we needed to use H Round Zinc Came 1/4 inch face to ensure a strong interior strength coupled with 3/8 Zinc Border Came. We solved this problem by using a standard grit Aanraku Ripple Bit. This allowed us to grind down each side of these very thick bevels so they could be inserted into the new round zinc came. However it was imperative that we grind each side equally so we practised on a bevel that we had in stock. Then through trial and error we set up the ripple bit to ensure removal of the same amount of glass from each side of the bevel before inserting them into the panel.

The following photo shows a portion of the panel with all of its pieces numbered, we then carefully took the panel all apart and that is when we found out how very thick the glass was in these old bevels.

In the next photo we have now taken the rub pattern and set up a wooden frame, complete with the 3/8 zinc border came, ensuring that we have the measurements exactly so it will fit back into the original wooden door which our client was getting restored. Please note on the right side there are a couple of pieces of the very old came originally used.

The last photo is of the completely restored panel. Fortunately we had a piece of old glass that matched the one broken piece in the panel. We cleaned each piece of glass, carefully measuring and cutting the H zinc came. After soldering the joints we use Glass Pro Stained Glass Putty to cement the glass and then cleaned with whiting, after which we applied Clarity Polish. In this particular case we did not patina any of the zinc came as we felt it was not required in this restoration.

Designer Unknown – Restoration by Bob & Flory Wilkins